What do you remember of your Dad, Melvin starting the business back in 1983?

N: I remember it being a really difficult time to be honest. I was 13 and Dad had been made redundant for the third time in as many years. He’d worked really hard to re-establish himself in his latest role and he’d done really well, so be told the parent company had gone bust was pretty devastating.

But as they say out of adversity comes opportunity and that’s how Birch was born. Dad went round his customers and asked if they’d support him if he went on his own and the vast majority of them did.

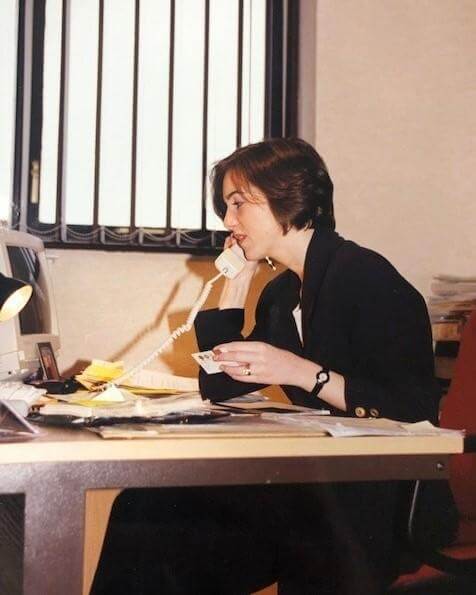

I remember Dad & Mum sat in the study in those early days doing invoices when mum had come back from her job at Boots. They worked as a team through those difficult years.

Melvin and Jean Birch outside Birch Print’s first HQ, Baker Road in Newthorpe, Nottingham

A: Prior to dad starting the business he had been made redundant twice in quick succession, so in one sense he almost had nothing to lose. Having said that, we also know that starting a business for anyone is a daunting prospect.

Dad had always been really successful in selling and this was his opportunity to throw himself into his own company. It was very much a team effort with my Mum in the early days managing the accounts.

I remember the excitement of getting their first premises too!

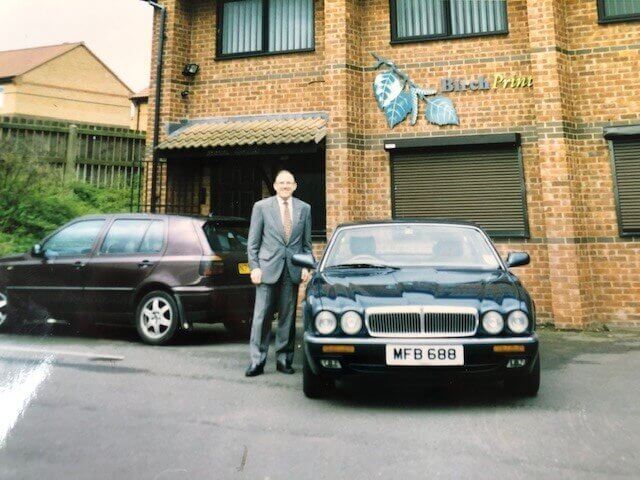

Melvin outside Birch Print’s second HQ, Southglade Business Park, Nottingham

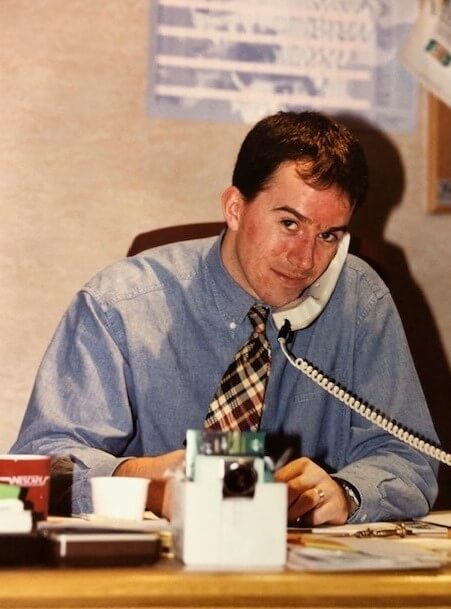

What was your involvement back then?

N: I remember back when everything was very analogue, Dad would bring the latest Carryfast rate cards home that needed updating and we literally had to colour them in so they could be scanned. There was lots of little stuff like that we started to see.

When they moved to Baker Road Mum had been doing the cleaning too, so when I was about 15 my Saturday morning job was to clean the office. I got £10!

A: The business started in 1983 and I came on board in 1985. I’d only just completed my A-Levels so had no experience in business or print at all! It was a case of soaking it all in and learning from my Dad.

From there I went into sales and started speaking to my own prospects and customers. Birch was, and still is a very relationship-led business and I couldn’t have had a better mentor from that aspect. Dad treated everyone from the guys on the shopfloor to the CEO exactly the same and with utter respect.

When did Melvin retire and hand the business to you?

N: So Dad retired in 1997. My wife & I had just had our first daughter (Sacha), so when Dad said he wanted to retire it was quite a big decision for us as to what to do. It was quite daunting. The business was at a point where it’s value for sale wasn’t great, particularly as Dad wanted to step aside, so we (Andrea and I) decided to give it a go. That was 26 years ago!

A: It was in 1997 and at that point, Dad had met all the goals he had set, including one of them being to retire at 55!

How did it feel to take on the business?

N: Really daunting to be fair. There were many highs and lows. When one of our big accounts went into administration I was on holiday and remember fearing that we wouldn’t be able to recover from that. That was quite a hopeless feeling. There have been many high’s though. You just need the highs to out value the lows!

A: For a while, Nigel and I had been managing most of the general day-to-day, so in one sense it was business as usual, however, to take on the full responsibility, particularly when we were quite young was a daunting prospect. The pressure of being able to continue to bring in the sales was heavy.

Having said that, we did relish the thought of being able to really push the business forward!

How has Birch changed over the years?

N: We’ve always been a family business. Dad & Mum, Andrea & I and my wife Jen. But our team are an extension of that and over the years we’ve had many great people work for us.

We’ve had to adapt and change, but our partnership with so many print companies has enabled us to do that. When new requirements come up, we’ve been able to reach out and find solutions. It’s one of the beauties of how we work.

As we’ve widened our supplier base, we’ve also been able to ensure that everyone we work with has the highest of standards and follows the industry standards or more. Print at one point, like many industries was unregulated, but now, with the introduction of sustainable resources, we know that any print we buy in the UK (or occasionally overseas) is sustainably sourced at the very least.

A: In one sense it hasn’t, in that our ethos of being a solutions-driven business has been constant. From the days when Dad was instrumental in creating the first barcoded consignment labels for the courier industry, to the use of video screens in welcome boxes!

In another sense, the changes have been quite considerable. In our first office, we had a fax machine….some of the team don’t even know what one of those is!

Dad had one of the first mobile phones. He was always looking at opportunities to be more efficient and embrace the latest technologies which has continued throughout the years.

We’ve always tried to be flexible and adapt to changes around us and that has held us in good stead over the years. This has included being sustainably focussed and over the last 20 years, we have introduced a biomass boiler, LED lighting, electric vehicles and latterly solar panels.

Our office address with a fax number!

How has the print industry changed in the last 40 years?

N: The technology around print has changed massively. When we started, artwork was literally cut and pasted onto boards then it would be shot by camera and a negative film would be made, all laid out by hand and very labour intensive. Then the Apple Mac came along and changed the face of print. From that point, technology moved really quickly and what used to take days could be done in hours and with more accuracy.

Litho printing presses became bigger, faster, quicker to set up, and greener with reduced chemical usage. Then came the digital presses that allowed short runs with almost litho quality. The quality you get now from digital is amazing. Back then you could really tell the difference between litho and digital but it was still huge.

Outsourcing so much of our work over the years has meant we have been able to work with some great companies that are leaders in print trends.

Way back, one of Dad’s main customers, Carryfast asked him to help with a new system for scanning and tracking parcels, which was unique at the time. Dad worked with some of the leading print companies to produce barcoded consignment notes and labels. It was pretty impressive at the time.

Our first logo!

A: Massively! When I first started in print, studios had no knowledge of an Apple Mac!

Our printers were using metal printing plates and they could only predominantly print on paper. When a business had an increase in prices, it meant price lists and price stickers etc all needed to be reprinted. Then the digital world exploded. Digital price lists would be emailed instead. Short runs are viable and it’s possible to print on many different substrates.

Digital technology for both artwork/repro and print methods has brought many opportunities.

Having said that, some of the older methods of foiling and embossing etc have come to the forefront again to add a special finish and make print more distinctive.

There may be less print around in one sense, but it just needs to work harder.

What have been the most memorable events of running the business and why?

N: We’ve done some great projects for our customers over the years. I used to love sending out all the Point-of-sale print for the Marston’s chain of pubs. It was hard work but satisfying. Similarly when DPD put a unique project to us it’s always a positive to see something go from being an idea tossed around to a finished product. Particularly when it’s well received.

But I’d say my most memorable stuff is when your team works well and you see someone grow and develop and become more than they initially expected. That’s really satisfying.

A: Wow, that’s a difficult one as there have been lots over the years.

Cracking open the champagne at various milestones, seeing amazing projects come to life; such as the collaboration with Hasbro on the personalised Monopoly game for DPD and working with the likes of the Inditex Group. We work with some fantastic customers who over the years have become friends. This is what makes coming to work every day enjoyable, as we continue to create and produce print solutions and make our customer’s lives that little bit easier. Having a great team to do that with is a bonus.

What’s been the hardest challenge and biggest business lesson?

N: One of the hardest challenges I find is the relentlessness of it. You can have a brilliant year and then the numbers are reset and you start again. Covid was super tricky, but I guess the lessons are that if the basics in your business are strong, you have good people, good processes, strong customers and strong financials, then when the difficult times come, you have the right tools to manage it. It doesn’t mean it’s not hard going, and you do have to put the hours in, but having those things in place gives you the best opportunity to succeed.

A: Having to close the doors on our internal print arm was a massive blow and taught us a difficult lesson. In reality we should never have taken it on in the first place. It was a combination of bad timing and naivety, and one that we came out stronger from. However, it’s not an experience I’d like to repeat.

If we’d never ventured into print production we’d have always wondered what if, but it taught us we were right to invest further with our print partners.

Covid was another massive challenge (obviously for everyone). Despite the challenges, it taught us to continue to be flexible and adapt to change, and by doing that we helped a fair number of our customers to really grow during that time.

What’s next for Birch?

N: Ooh now that’s a good question. Well, we’ve recently expanded with our new Fulfilment & Logistics service for online retailers. That’s going really well and we’re just implementing new software to increase efficiency there.

We’re developing our packaging offering and we’ve done lots of different forms of packing and product packaging for the smaller retailers again, so that’s something we’re excited about.

We’re always looking for the next steps and opportunities, and there’s generally always plenty to pursue. We’re looking forward to the next challenge from our customers who ask us to do something new and unique for them. There’s nothing like being pushed to find the next new thing.

A: We have a relatively young team who are eager to help us continue to explore the opportunities around us. I think Social Media will play a large part as we move ahead, and the Fulfilment side of our business will continue to grow.

Print is definitely not dying; it just needs to work hard, and we’re ready to continue to help it do just that!

Celebrating 40 years of Birch